Resupply from another warehouse¶

A common use case for multiple warehouses is to have one central warehouse that resupplies multiple shops, and in this case, each shop is considered a local warehouse. When a shop wants to replenish a product, the product is ordered to the central warehouse. Juniper allows the user to easily set which warehouse(s) can resupply another warehouse.

Configuration¶

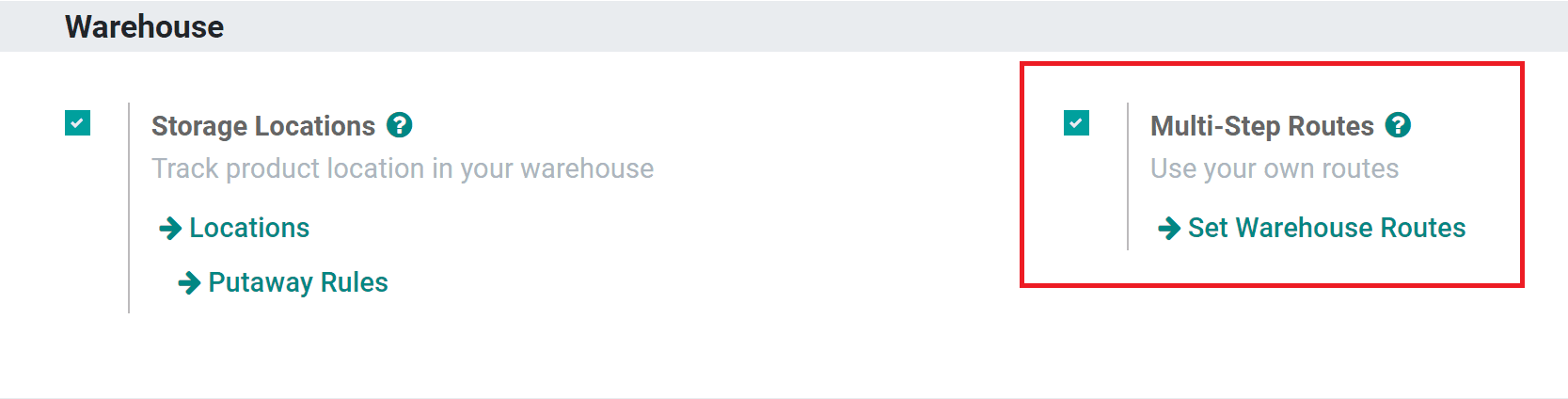

To resupply from another warehouse, first go to and activate Multi-Step Routes. Then, click Save to apply the setting.

View all the configured warehouses by going to .

Create a new warehouse by clicking Create. Then, give the warehouse a name and a Short Name. Finally, click Save to finish creating the warehouse.

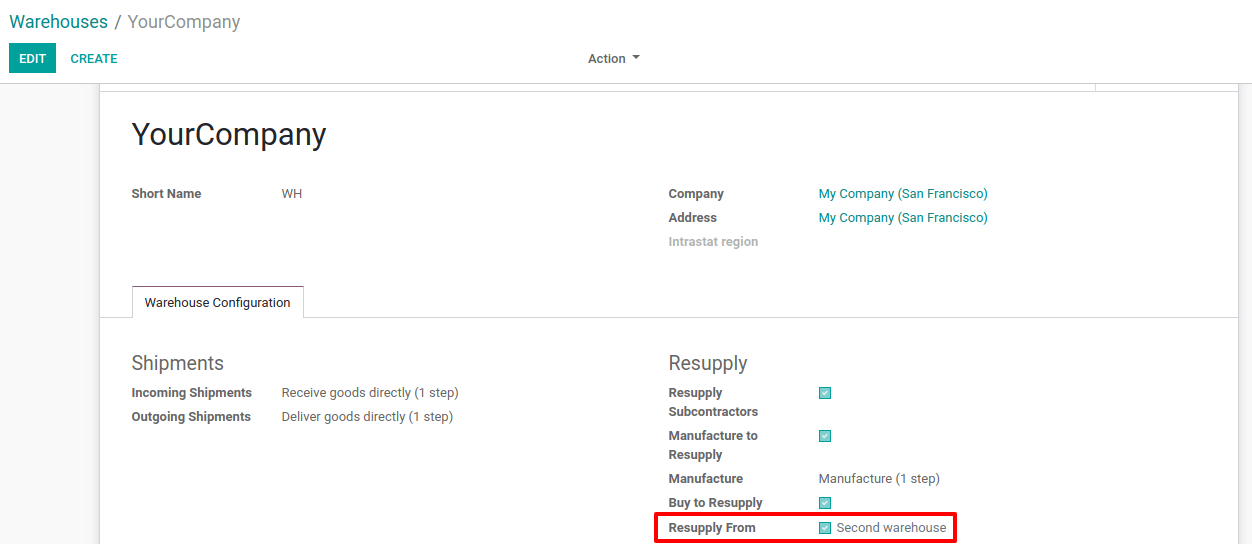

After that, go back to the Warehouses page and open the warehouse that will be resupplied by the second warehouse. Then, click Edit. In the Warehouse Configuration tab, locate the Resupply From field, and check the box next to the second warehouse’s name. If the warehouse can be resupplied by more than one warehouse, make sure to check those warehouses’ boxes too. Finally, click Save to apply the setting. Now, Juniper knows which warehouses can resupply this warehouse.

Set route on a product¶

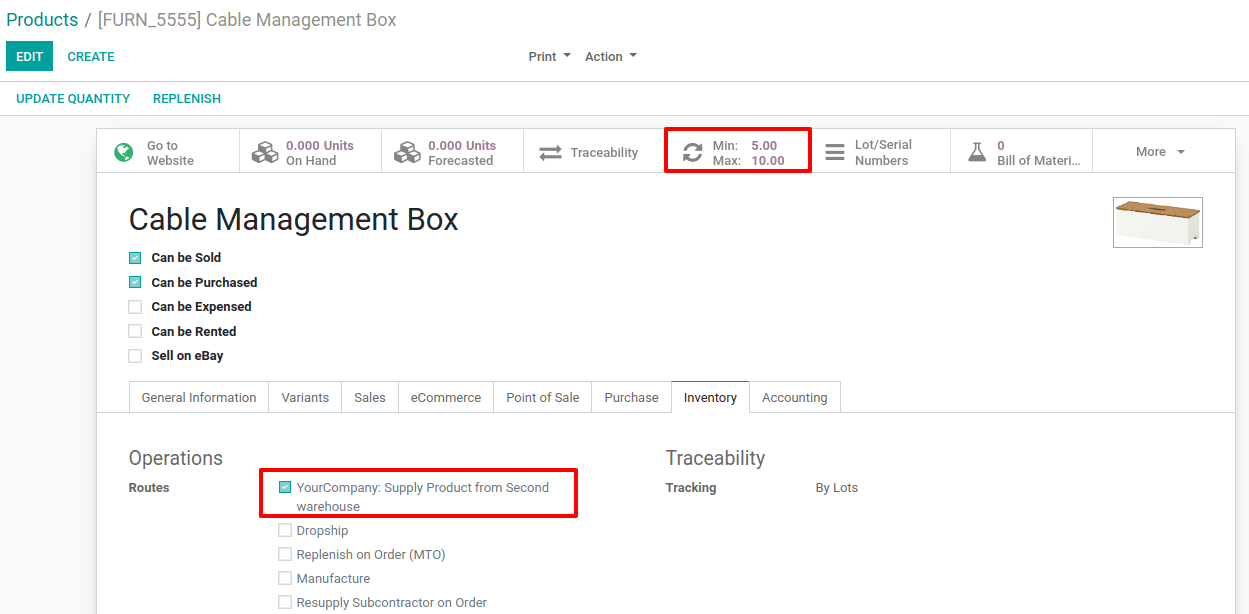

After configuring which warehouse(s) to resupply from, a new route is now available on all product forms. The new route appears as Supply Product from [Warehouse Name] under the Inventory tab on a product form. Use the Supply Product from [Warehouse Name] route with a reordering rule or the make to order (MTO) route to replenish stock by moving the product from one warehouse to another.

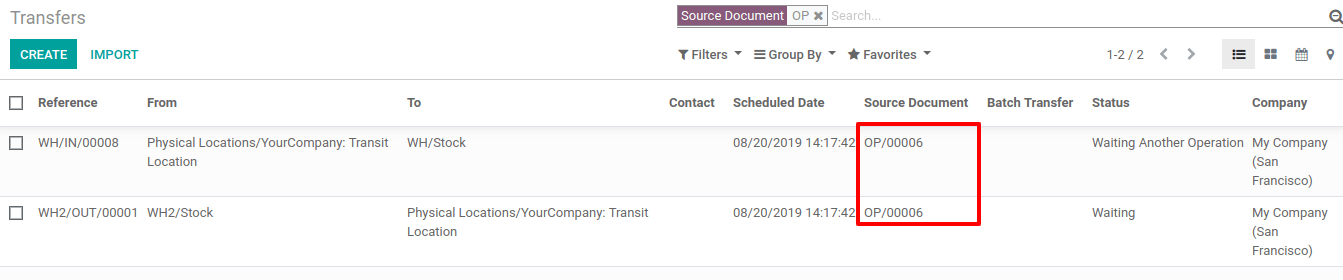

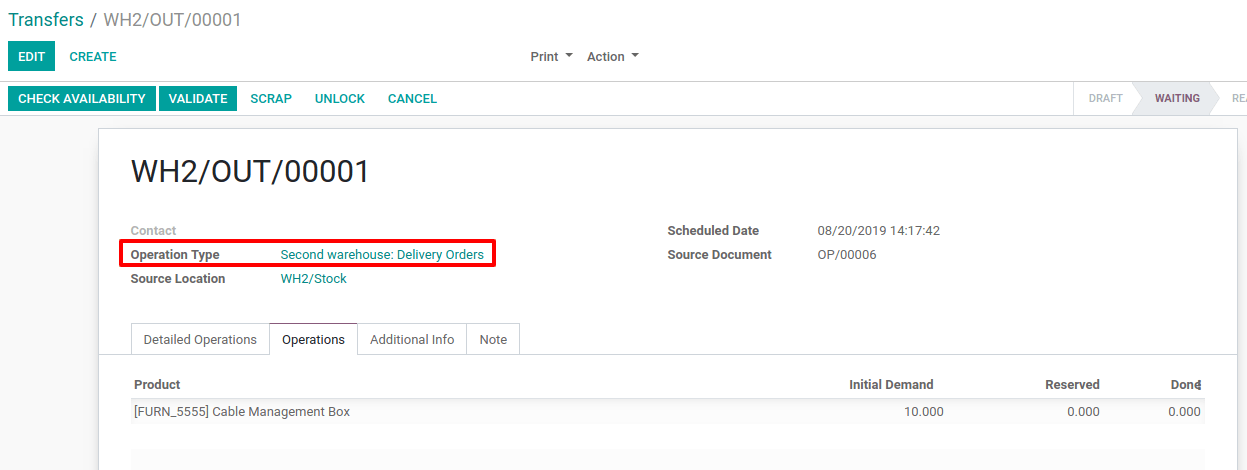

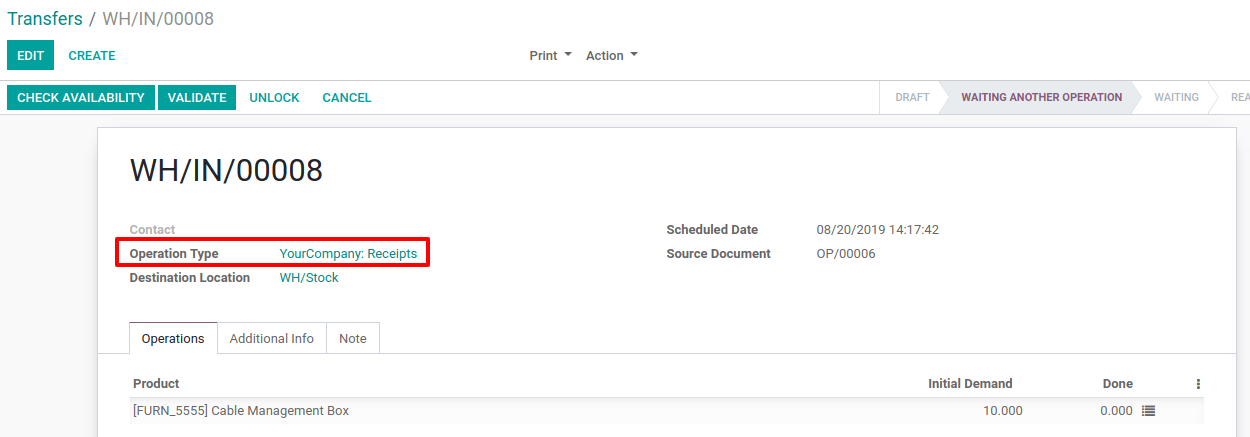

When a product’s reordering rule is triggered and the product has the Supply Product from [Warehouse Name] route set, Juniper automatically creates two pickings. One picking is a delivery order from the second warehouse, which contains all the necessary products, and the second picking is a receipt with the same products for the main warehouse. The product move from the second warehouse to the main warehouse is fully tracked in Juniper.

On the picking/transfer records created by Juniper, the Source Document is the product’s reordering rule. The location between the delivery order and the receipt is a transit location.